Please feel free to contact us anytime. In this category you will find all of our vacuum pumps vacuum equipment vacuum accessories and fittings. Composite vacuum bagging equipment australia.

Composite Vacuum Bagging Equipment Australia, ACP Composites carries vacuum bagging sealant tape mold release shrink tape aero-veil and several other products essential in the vacuum bagging process. Contents 1 Introduction Understanding the theory of vacuum systems and the advantages of vacuum bag laminating 2 Vacuum Bagging Equipment Evaluating the equipment and materials used in. Vacuum bagging systems and supply kits include all the materials you will need to make a few small parts plus detailed instructions and pump with regulator assembly. All kits can be altered or modified to fit each customers specific needs.

Vacuum Bagging Materials Overview Youtube From youtube.com

Vacuum Bagging Materials Overview Youtube From youtube.com

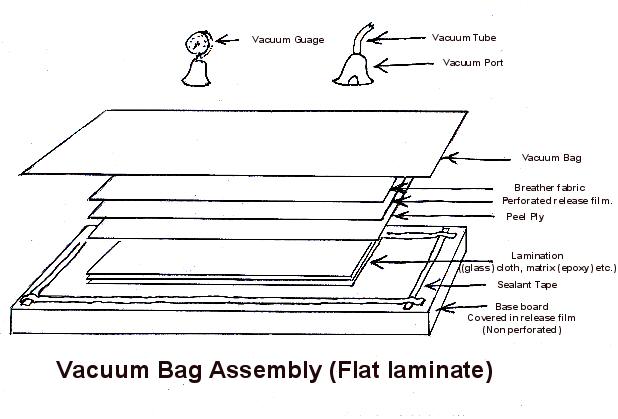

Introduction Photo credit IStock Photo. With the precision of German design Smartech offers you the best in industrial bags that will set your business and projects apart. The material is then covered with an impervious film the vacuum bag which is sealed around the edge of. Composites and Vacuum Bagging Materials.

In building composite products vacuum bagging materials play a significant role.

Read another article:

For the best bagging materials youve found the right page. Pressurizing a composite lamination serves several functions. Vacuum Bagging Techniques A guide to the principles and practical application of vacuum bagging for laminating composite materials with WEST SYSTEM Epoxy. Vacuum bagging systems and supply kits include all the materials you will need to make a few small parts plus detailed instructions and pump with regulator assembly. Use the sub-categories below to look at specific ranges within our vacuum equipment.

Source: pinterest.com

Source: pinterest.com

Whether you are just getting into composites or updating your current shops capabilities we have the materials needed to outfit your shelves and work benches properly and. This kit includes the standard bagging materials needed to make a part. In this category we have Nylon Vacuum bagging film sealing tape peel ply release film etc. In this category you will find all of our vacuum pumps vacuum equipment vacuum accessories and fittings. How To Build A Vacuum Bag Youtube Vacuum Bags Vacuum Surfboard Shapes.

Source: pinterest.com

Source: pinterest.com

Vacuum bagging is a technique employed to create mechanical pressure on a laminate during its cure cycle. Vacuum bagging When discussing composites resin generally refers to the resin systemmixed or cured resin and hardenerrather than unmixed 105 epoxy resin Modern room-temperature-cure adhesives have helped to make vacuum bag laminating techniques available to the average builder by eliminating the need for much of the sophisticated and expensive equipment required for laminating. Vacuum Bagging Equipment and Techniques for Room-Temp Applications Put Your Vacuum Bagging Knowledge to the Test Take Our Vacuum Bagging Quiz. Whether you are just getting into composites or updating your current shops capabilities we have the materials needed to outfit your shelves and work benches properly and. 3 Layer Flute Laminator At Shanghai Exhibition Laminator Flute Exhibition.

Source: rowetrading.com.au

Source: rowetrading.com.au

Pressurizing a composite lamination serves several functions. This category does not include vacuum bagging consumables which are listed in a separate category. From starter pump to industrial capacity Fibre Glast offers vacuum pumps and generators to suit the requirements of nearly any vacuum bagging application. Experts and mass-producers know the benefits and intricacies of vacuum bagging but for the uninitiated vacuum bagging is the method of using a vacuum to extract air and compress layers of composite materials during the curing process. Vacuum Bagging Supplies Rowe Trading.

Source: boatcraft.com.au

Source: boatcraft.com.au

Use the sub-categories below to look at specific ranges within our vacuum equipment. Vacuum Bagging Equipment 23 Taps and Fittings 12 Mould Release Agents 2 Core Material 4 Safety Equipment 0 Services 0 Clearance items 3 Uncategorized 10 PAGES. In this category you will find the vacuum bagging materials and equipment that are most commonly used when undertaking resin infusion of composite parts. Experts and mass-producers know the benefits and intricacies of vacuum bagging but for the uninitiated vacuum bagging is the method of using a vacuum to extract air and compress layers of composite materials during the curing process. Vacuum Bag Stuff Boatcraft Pacific The Home Of Wooden Boat Building.

Source: hu.pinterest.com

Source: hu.pinterest.com

12-14 Production Ave Molendinar. Technical Documents Blog Contact Us. This means you can maximise the physical properties of the composite materials such as. I will include as envelope bagging the bagging of things down to a vacuum tight table. Buy Airless Paint Sprayer With 7 6m Hose 750w From Kogan Com To Produce A More Effective And Efficient Outcome For Your Paint Sprayer Sprayers Easy Paintings.

Source: ar.pinterest.com

Source: ar.pinterest.com

Use the sub-categories below to look at specific ranges within our vacuum equipment. Technical Documents Blog Contact Us. Showing 116 of. In this category you will find the vacuum bagging materials and equipment that are most commonly used when undertaking resin infusion of composite parts. Looking For A Great Way To Quickly Clean Your Vehicle Then This Is Best For You Convenient Wet And Dr Car Vacuum Cleaner Portable Vacuum Cleaner Car Vacuum.

Source: indiamart.com

Source: indiamart.com

Vacuum Bagging Equipment 23 Taps and Fittings 12 Mould Release Agents 2 Core Material 3 Safety Equipment 0. It removes trapped air between layers. First it removes trapped air. Pressurizing a composite lamination serves several functions. .

Source: vacmobiles.com

Source: vacmobiles.com

Vacuum Bagging Equipment 23 Taps and Fittings 12 Mould Release Agents 2 Core Material 4 Safety Equipment 0 Services 0 Clearance items 3 Uncategorized 10 PAGES. Vacuum Bagging Equipment and Techniques for Room-Temp Applications Put Your Vacuum Bagging Knowledge to the Test Take Our Vacuum Bagging Quiz. For the best bagging materials youve found the right page. Vacuum bagging and vacuum bagging supplies Vacuum bagging is a crucial process to achieving the best and strongest finish in composite projects. Vacuum Pump Systems For Resin Vacuum Infusion Vartm Vacuum Bagging.

Source: columbus-tech.com

Source: columbus-tech.com

Check out our high quality products for equipment used for vacuum bagging and infusion composite projects. All kits can be altered or modified to fit each customers specific needs. Composites and Vacuum Bagging Materials. This a really common and useful way to deal with lots of problems. Columbus Pioneer The Innovative Vacuum Press Modular System For Laminated Bending Vacuum Forming Veneering And Shaping Of Plastics Thermoplastics Composite Materials.

Source: easycomposites.co.uk

Source: easycomposites.co.uk

First it removes trapped air. Vacuum Bagging Equipment and Techniques for Room-Temp Applications Put Your Vacuum Bagging Knowledge to the Test Take Our Vacuum Bagging Quiz. Technical Documents Blog Contact Us. Use the sub-categories below to look at specific ranges within our vacuum equipment. Vacuum Bagging Starter Kit Easy Composites.

Source: easycomposites.co.uk

Source: easycomposites.co.uk

All kits can be altered or modified to fit each customers specific needs. This kit includes the standard bagging materials needed to make a part. Products Vacuum Bagging and Infusion. From starter pump to industrial capacity Fibre Glast offers vacuum pumps and generators to suit the requirements of nearly any vacuum bagging application. Vacuum Bagging Starter Kit Easy Composites.

Source: amazon.in

Source: amazon.in

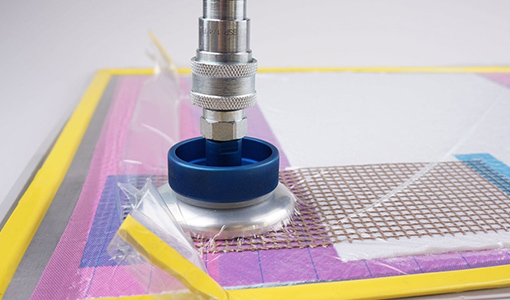

The range includes nylon bagging films release films breatherbleeders sealant tapes infusion mediums vacuum connections and plumbing and vacuum pumps. If you have a one-off MDF or tooling board mold like the rudder molds above on the right that doesnt have enough flange for a bag and wouldnt hold vacuum if it did go ahead and bag it right down to a flat table. Vacuum bagging When discussing composites resin generally refers to the resin systemmixed or cured resin and hardenerrather than unmixed 105 epoxy resin Modern room-temperature-cure adhesives have helped to make vacuum bag laminating techniques available to the average builder by eliminating the need for much of the sophisticated and expensive equipment required for laminating. Supplying Australia and international customers including New Zealand China Singapore and India Ironbark. Vacuum Bagging Kit 1 4 Hp Diy Do It Yourself Kit For Carbon Glass Composite Amazon In Industrial Scientific.

Source: wacker.com

Source: wacker.com

Vacuum bagging is a method for creating mechanical pressure on a laminate during its cure cycle. This kit includes the standard bagging materials needed to make a part. Vacuum bagging is a very flexible process for consolidating fibre-reinforced polymer laminates of a wide range of shapes and sizes. The composite to be consolidated eg. Elastosil For Composite Molding Wacker Chemie Ag.

Source: easycomposites.co.uk

Source: easycomposites.co.uk

These items are the same items used in composite shops across the world. This category does not include vacuum bagging consumables which are listed in a separate category. In this category you will find the vacuum bagging materials and equipment that are most commonly used when undertaking resin infusion of composite parts. Vacuum bagging is a technique employed to create mechanical pressure on a laminate during its cure cycle. Vacuum Bagging Starter Kit Easy Composites.

Source: cfint.com.au

Source: cfint.com.au

In this category you will find all of our vacuum pumps vacuum equipment vacuum accessories and fittings. In this category we have Nylon Vacuum bagging film sealing tape peel ply release film etc. With an extensive range of stock ranging from fibreglass supplies carbon fibre and aramid products such as Kevlar through to epoxy resins and vacuum bagging equipment Dick Garrard and Ironbark Composites have composites covered. This a really common and useful way to deal with lots of problems. Home Composite Solutions Composites Fibreglass International.